Accredited.

Researched.

Compliant.

Formwork Systems.

About Arkform

ARKFORM promotes the use of ICF’s in New Zealand. We work with suppliers and contractors to get the best deals when building a home.

When working with ARKFORM, we will connect you with all you need to make your ICF build easy whether you are building commercially or privately.

Featured Projects

Barrack Road

Athens Road

Add to the front of an old bungalow to make the house habitable for a larger extended family. ICF basement went up very quickly and with the easily fitted Polystyrene floor support a warm and quiet basement was created where late night work and noise is possible because of the great insulation power of the ARKFORM ICFs. Very satisfied customers.

Cardigan Street

An aging and borer ridden old house was replaced with 5 spectacular units. Incredible low maintenance. Wash it down every year is it! Residents just got a note from their power company “You may want to consider shifting to the ‘low use’ pricing plan” They also run two electric vehicles out of this unit. Hard to argue with the power company as they used the heat pump 2 days in winter and 2 in summer. The R4 walls and concrete midfloors make a very safe, very quiet, very dry and easy to heat/cool house.

East Street

‘Help’ said the developer. ‘I can’t get my formwork. Can you build you build the foundations around the steel work that’s already there.’ Making things happen is what we do. A few days later and the formwork was all in place (despite some misaligned steel placement) and the build could proceed as planned. ‘Love what you guys do and love the product’ was the response from the developer!

Montgomery Road

“We need retaining walls that are house walls.” That was the call from the architect. Blocks delivered and placed. Project finished very quickly. Builder couldn’t believe walls were ready for a pour at end of third day. Walls performing perfectly. What else needs to be said!

Questions you may have…

Frequently asked questions

Do we have BRANZ appraisal?

Not all ICF’s in NZ are BRANZ appraised. Our supplier has BRANZ appraisal for fire and sound testing. Everything else is covered by the NZS3901 and 3109 in-situ masonry codes.

Polystyrene is not very strong. How strong are ARKFORM buildings?

Very strong! ARKFORM is a solid concrete and steel structure, far stronger than timber, with polystyrene attached inside and out to give it wonderful insulation ratings and save you money on heating and cooling.

Can ARKFORM blocks be cut?

Sure can! Circular and hand saws (which make a bit of a mess so cut in a confined space for site tidiness) and hot knives. We lease hot knives of various shapes for the duration of the job so that any architectural shape can be achieved and there is very little waste – blocks and rebates can be cut to reuse the blocks in other situations.

So, what sort of insulation values does an ARKFORM block have?

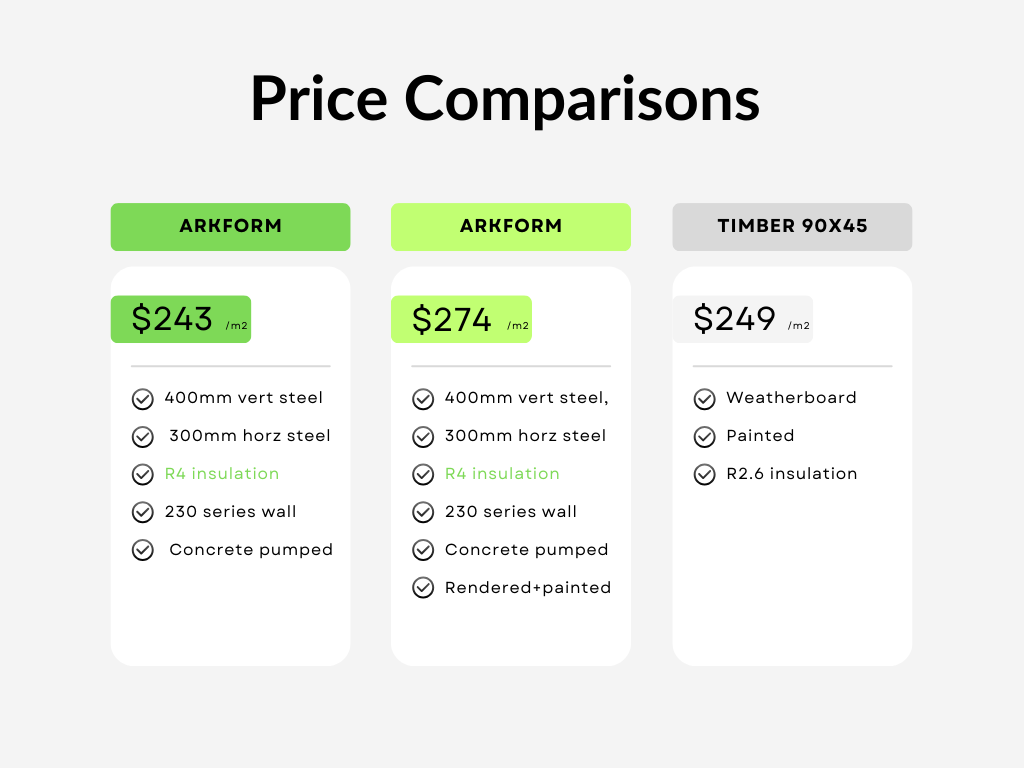

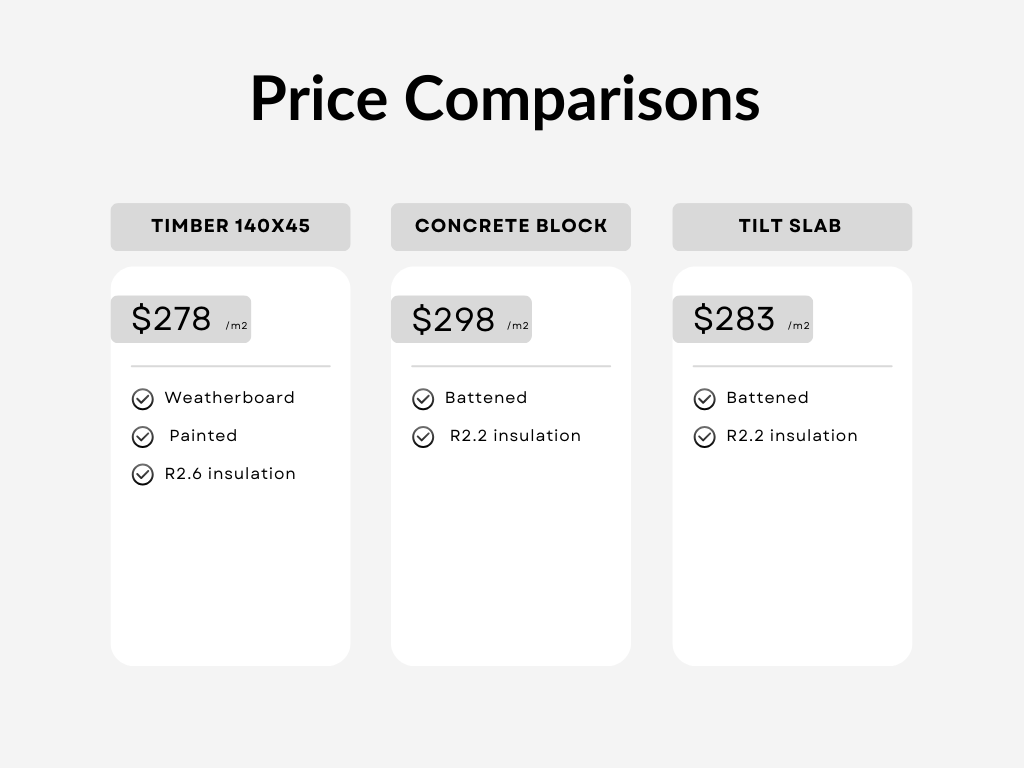

Well one thing we can say is that it far exceeds the new H1 regulations! When combined with the concrete all our walls exceed R=4. Our foundations, when the concrete slab is taken into account would be R=2 BUT if you are using 90mm timber walls on top of that it might be as low as R=1.7 because the top of the block needs to be rebated to get concrete cover for the bolts holding the bottom plate. The new H1 regulations mean that nearly everything will need to be in 140mm wide timber anyway to get timber walls to achieve the kind of R ratings easily achieved by ARKFORM panels. See the product manual for more details.

Polystyrene is often called EPS – what is EPS?

EPS is a lot of hot air! About 98% of polystyrene is air trapped in cells. It is made for our supplier ECO-Block right here in NZ by ‘expanding’ very small beads into bigger ones in a mold surrounding the rails that are embedded in the block vertically every 200mm. Thus the term Expanded PolyStyrene or EPS for short.

Does EPS absorb water? What about capillary action?

NO to both. Its ‘closed cell’ so the cells cannot absorb water. There is some absorption in the gaps between the cells but the fact that EPS is used in ocean buoys and now extensively under motorway construction with constant contact with ground water probably says it all! Furthermore it doesn’t age either. See the product manual for further details.

People say EPS is a fire hazard. Is that true?

ARKFORM uses ECO-Block products and it is manufactured here in New Zealand with the latest globally approved fire retardant materials. Of course, everything burns if it gets hot enough – even metals and plaster burn in a firestorm – but unlike timber products EPS is self extinguishing – i.e. it only burns/melts if you hold a flame to it. Take the flame away and it stops burning. Furthermore, if burnt it doesn’t release the same toxic chemicals that treated timber does.

How Eco friendly is ARKFORM?

We use ECO-Block for a reason! When it’s being manufactured any waste is reground and added back in. Anything that comes off site should not be taken to the dump but to a recycling plant where it can be turned into material for skirtings, architrave and picture frame or ground and used for drainage applications or soil aeration. EPS is a very eco friendly material compared to many other products in the construction industry.

Is EPS toxic?

Unlike timber EPS has no toxic chemicals in it and no CFC or HCFC is used in its production.

Have a project in mind? Let’s talk.

Sorry. This form is no longer accepting new submissions.